Legacy Motors

Legacy Directional’s owned, proprietary line of drilling mud motors provides the ability to manage a comprehensive fleet, fully controlled throughout the product life cycle – from design and manufacturing to assembly and service, dedicated to client-specific needs. This allows for fit-for-purpose solutions, enhanced response times, and the ability to apply lessons learned from each well to improve the motor fleet in fast cycle time.

Legacy Motors is supported by state-of-the-art facilities with over 25,000 square feet for manufacturing, along with a 17,000 square feet assembly and service center. This footprint supports the design, engineering, manufacturing, and assembly of a complete range of mud-lubed motors, ranging from 3.75″ to 9.63″ in diameter.

Legacy owning its own line of drilling mud motors and having complete control and management over the process from start to finish provides a transformative impact for our customer base. See how:

50+ Single Run VCL Wells Completed

15,138 Feet

Longest Motor Run

Hot Hole Records

15,138 Feet (VCL)

104 Drilling Hours

145.7 Average Feet per Hour

356°F: Maximum Temperature

Partnering with Legacy

Unwavering Quality Commitment: At Legacy Motors, quality extends beyond manufacturing, ensuring every client experiences excellence throughout their operation.

Advanced Facility & Equipment: Our state-of-the-art facility is equipped to support all aspects of drilling motor design, manufacture, and service, providing a foundation for unmatched product quality.

Expert Planning & Engineering: With detailed motor service documentation and facility design guidance, we ensure operational efficacy and minimal downtime.

Sophisticated Analytics Services: Our services go beyond immediate support, offering deep analytical insights and strategic guidance for continuous operational improvement.

Holistic Incident Analysis: Equipment Failure and Severe Damage Analysis leverage comprehensive data to offer actionable insights, ensuring clear, understandable reports for all audiences.

Advanced Drilling Performance Optimization: Incorporating BHA modeling, hydraulics, torque and drag, and critical speed analysis, we optimize drilling operations to reduce costs and downtime.

Continuous Product and Process Improvement: Our commitment to innovation and excellence drives ongoing product enhancements, setting new industry standards.

Legacy Motors is proudly ISO 9001 certified, a testament to our unwavering commitment to quality management and customer satisfaction. This prestigious recognition highlights our dedication to excellence and continuous improvement across our operations.

Legacy’s owned motor fleet guarantees the availability of fit-for-purpose motors and power sections tailored to customer requirements.

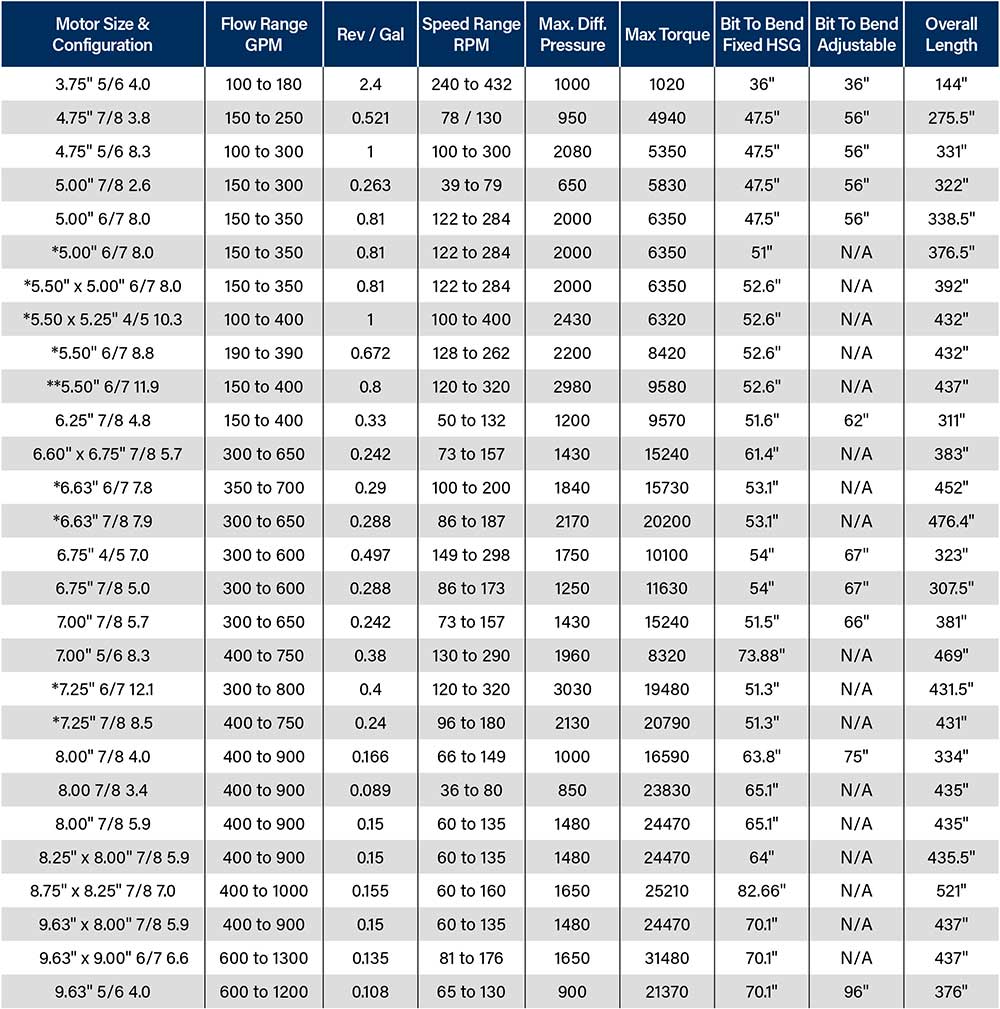

Motor Specifications

* Denotes motors available with titanium flex shaft transmission

** Denotes proprietary power section with titanium flex shaft transmission

A variety of combo motors are available upon request