Motor Manufacturing

Facilities

Facilities

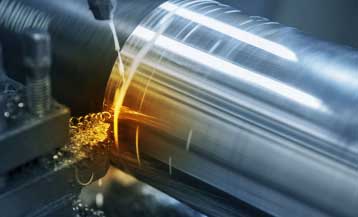

The engineering and manufacturing of Legacy’s drilling motors are housed at our facilities located in Louisiana and Texas, touting over 25,000 square feet of space dedicated to manufacturing and 17,000 square feet used for assembly and service. Our facility is outfitted with an array of advanced manufacturing technologies, including several programmable mills, grinders, and welding machines, alongside a variety of manually operated equipment. This combination allows us to offer unparalleled precision and flexibility in production.

Operations

100% of Legacy Motors are manufactured in-house which allows us to control quality from design & engineering to manufacturing, assembly, and servicing to operations in the field.

At the heart of our operations is a welding unit specialized in applying carbide-based hard metal to critical wear areas such as wear pads, drive coupling lobes, and stabilizers. Thanks to our precision PTA (Plasma Transferred Arc) machines, we ensure each wear pad is uniformly coated with a consistent thickness, enhancing durability and performance.

Processes

Legacy Motors also employs a sophisticated shot peen process, specifically designed to mitigate surface cracking in parts prone to high stress concentration. By targeting vulnerable areas like threaded connections, radii, and sharp corners, this process effectively reduces residual stresses and significantly lowers the risk of fatigue cracking in critical components

Capabilites

Furthermore, our facility is equipped with zinc phosphating capabilities, a critical treatment that allows parts to better retain oil and lubricating compounds. This not only prevents corrosion but also minimizes the risk of thread galling, ensuring our products maintain their integrity and performance over time.